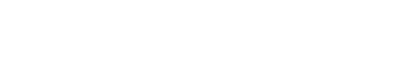

葉菜工廠采用物聯(lián)網(wǎng)和工業(yè)化思路,創(chuàng)新集成了信號(hào)采集、信息處理、設(shè)備控制等模塊,使用淺液流種植床進(jìn)行水培蔬菜生產(chǎn),旨在實(shí)現(xiàn)蔬菜從播種到采收全過(guò)程現(xiàn)代化、自動(dòng)化、智能化、可追溯的管控。該蔬菜工廠具有可模塊化建設(shè)的特點(diǎn);其生產(chǎn)的綠葉蔬菜不僅避免了傳統(tǒng)農(nóng)業(yè)中常見的大田蟲害,連作病害,土傳病害等問題,且可以在節(jié)水90%,節(jié)肥70%的優(yōu)勢(shì)下實(shí)現(xiàn)全年不間斷生產(chǎn),每公頃蔬菜工廠年產(chǎn)量可高達(dá)180噸,可為國(guó)內(nèi)蔬菜市場(chǎng)源源不斷地提供新鮮、安全的蔬菜480萬(wàn)棵以上。

Leafy vegetable factory

Leafy vegetable factory is designed based on the idea of IoT (Internet of Things) and industrialization. It aims to make all processes of vegetable production be intelligent, automatic, and traceable, by integrating multiple modules including signal acquisition, information processing, controllers, and using NFT-based hydroponic growing units. This factory is easy to reconstruct at anyplace due to the modular design method. Compared to open field cultivation, cultivation in the leafy vegetable factory can avoid insects, soil-borne disease, and crop continuous cropping obstacle, in the meantime saving 90% water and 70% fertilizer applying. The annual vegetable production of this factory can reach 180 t/hm2, which provids more than 4.8 million heads of fresh and safe vegetables per hectare to the market.